Crafted specifically for precision, the blood in a centrifuge is additionally improved by digital and mechanical enhancements. Intelligent balancing systems automatically eliminate unbalanced loads, improving performance as well as safety. Materials such as reinforced polymers and high-grade aluminum are becoming standard in rotor production, reducing wear and maximizing life in operation. Real-time sensors of temperature and speed offer feedback for reliable results. These developments not only improve separation efficiency but also allow for the achievement of stringent laboratory standards. With increasing research needs, blood in a centrifuge technology develops further to ensure better reliability and reproducibility.

The diversity of blood in a centrifuge applications shows its diversity to modern technology. Aerospace engineers utilize it to check the material properties under intense centrifugal stress. Nanotechnology utilizes it to segregate particles at micro and nanolevel for analysis and manufacturing purposes. Hospitals rely on blood in a centrifuge for testing, ensuring accurate plasma and serum analysis. Food processing industries utilize it to ensure product purity and uniformity. Additionally, educational laboratories employ blood in a centrifuge in teaching and experimentation, whereby students learn fundamental physics, chemistry, and biology concepts through hands-on demonstration.

blood in a centrifuge will integrate digital intelligence and cutting-edge engineering in the years to come. Complex algorithms will auto-tune parameters for optimum efficiency and safety. Energy-optimized designs will keep operating costs at a minimum and help support global green efforts. Robotics integration will facilitate round-the-clock unattended operation in big production setups. Modular design will provide ease of customization, allowing users to set up blood in a centrifuge for specific scientific or industrial uses. These improvements will allow blood in a centrifuge to not only increase performance but also establish new standards for automation, accuracy, and sustainability in the lab environments of the future.

For optimal performance, blood in a centrifuge equipment needs to be handled cautiously and carefully. Operators need to ensure that rotors are balanced before use to avert vibration and wear. Regular cleaning of inner and outer surfaces prevents residues from building up that can impact results. Electric wiring should be inspected for loose or damaged cables. Storage of blood in a centrifuge in a clean, temperature-controlled environment keeps its components. Regular professional maintenance and replacement of worn parts on schedule ensure smooth and efficient use of the device over time.

Used in many applications, a blood in a centrifuge uses rotational motion to facilitate material separation. Working through centrifugal force, it accelerates sedimentation, allowing scientists to sort particles based on density. Used extensively in laboratories, production plants, and environmental testing, the blood in a centrifuge simplifies processes that would otherwise be tedious. Flexible, it can be used in anything from clinical diagnostics to food and drinks. With continuing improvement in rotor design and balance technology, blood in a centrifuge today offer improved stability, endurance, and accuracy of data than before.

Q: What safety measures are important when operating a centrifuge? A: Always ensure the rotor is balanced, the lid is securely closed, and safety locks are engaged before starting operation. Q: What types of centrifuges are available? A: Common types include micro, benchtop, refrigerated, and ultracentrifuges, each suited for specific laboratory or industrial applications. Q: Why is balancing samples important for a centrifuge? A: Imbalanced samples can cause vibration, noise, and mechanical stress, potentially damaging both the rotor and the instrument. Q: What materials can be processed in a centrifuge? A: A centrifuge can handle liquids, suspensions, and even some emulsions, depending on its speed and rotor type. Q: How long can a centrifuge run continuously? A: Run time depends on the model and workload—most can operate from a few minutes up to several hours under proper temperature control.

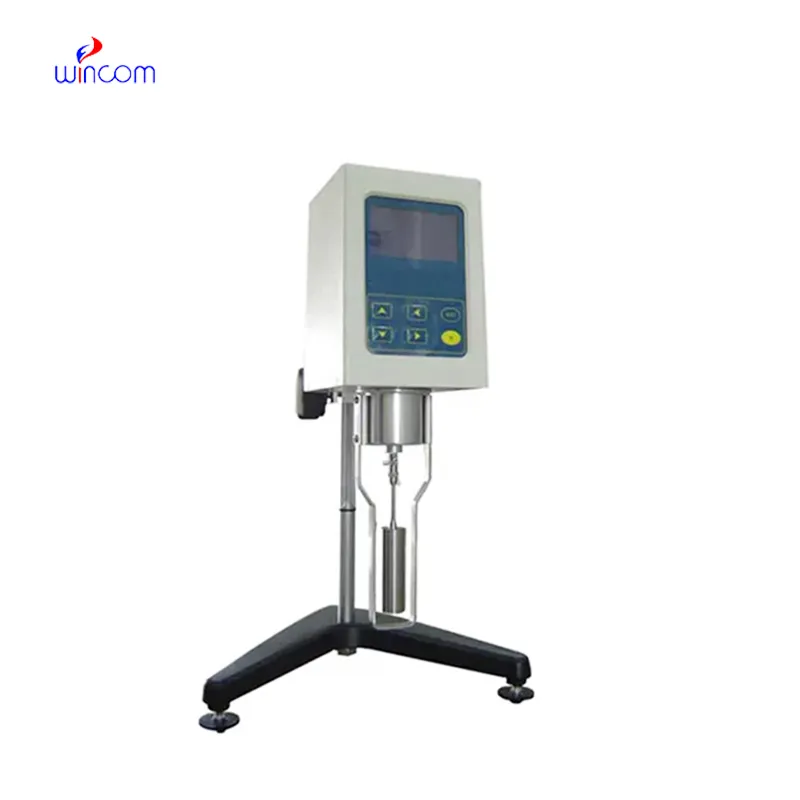

The centrifuge operates quietly and efficiently. It’s compact but surprisingly powerful, making it perfect for daily lab use.

I’ve used several microscopes before, but this one stands out for its sturdy design and smooth magnification control.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you please provide more information about your microscope range? I’d like to know the magnif...

Hello, I’m interested in your centrifuge models for laboratory use. Could you please send me more ...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China