A centrifugal clutch is based on a combination of speed, pressure, and design geometry. The development of more advanced rotor designs has optimized airflow and reduced heat generation when operating. Programmable memory is featured in most systems, allowing users to store frequently used parameters to maximize efficiency. Additionally, power-saving motors and sound-dampening enclosures minimize lab discomfort. The ability to spin micro and macro volumes with the same reproducibility gives centrifugal clutch equipment an edge both in the research and industrial settings. As technology advances, it remains to be at the forefront of precision and productivity.

Clinical laboratory environments utilize centrifugal clutch as an important tool for proper diagnosis. Blood banks utilize it to efficiently isolate red cells, plasma, and platelets. Research laboratories employ centrifugal clutch to examine tissue samples for cellular and molecular studies. In the energy industry, it assists in the manufacture of biofuels by isolating the biomass components. Food scientists employ centrifugal clutch to reclaim fats and purify proteins while preparing products. The numerous applications reflect its capacity to enhance data reliability, process control, and yield output in a wide variety of industries and research applications.

Future trends show that centrifugal clutch will become more intelligent, miniaturized, and green. Researchers envision systems capable of learning for themselves and optimizing their performance from previous data results. Integration within digital laboratory workflows will render operations, from sample entry to data reporting, more seamless. Increased automation will free researchers from manual monitoring, allowing more focus on analysis. In industrial processes, centrifugal clutch will have a role in cleaner production through the reduction of waste and energy usage. It is a step toward smarter scientific instrumentation that adapts to the challenges of technology.

Well-maintained centrifugal clutch assure trouble-free operation and optimize equipment longevity. Users must ensure balanced loading to prevent excessive stress to bearings. Regular cleaning of the rotor, chamber, and seals reduces cross-contamination. Regular lubrication and calibration ensure mechanical accuracy. Logs of maintenance, checklists, and other records facilitate quality control and inspection for compliance. Internal humidity and dust exposure should be reduced. Laboratories use preventive maintenance instructions to guarantee that centrifugal clutch delivers constant high performance with little downtime and repair.

centrifugal clutch revolutionized laboratory and industry processes of substance separation forever. By speeding up the sample at high speed, they produce an immense force that separates mixtures based on particle density. This is the mechanism that enables efficient extraction of biological compounds, chemicals, and nanoparticles. Laboratories apply centrifugal clutch for analysis, purification, and research. In industry, they enable the refining of oil and food quality analysis. Small tabletop units and industrial units both use the same fundamental principle—precision with rotational energy and controlled acceleration.

Q: What safety measures are important when operating a centrifuge? A: Always ensure the rotor is balanced, the lid is securely closed, and safety locks are engaged before starting operation. Q: What types of centrifuges are available? A: Common types include micro, benchtop, refrigerated, and ultracentrifuges, each suited for specific laboratory or industrial applications. Q: Why is balancing samples important for a centrifuge? A: Imbalanced samples can cause vibration, noise, and mechanical stress, potentially damaging both the rotor and the instrument. Q: What materials can be processed in a centrifuge? A: A centrifuge can handle liquids, suspensions, and even some emulsions, depending on its speed and rotor type. Q: How long can a centrifuge run continuously? A: Run time depends on the model and workload—most can operate from a few minutes up to several hours under proper temperature control.

I’ve used several microscopes before, but this one stands out for its sturdy design and smooth magnification control.

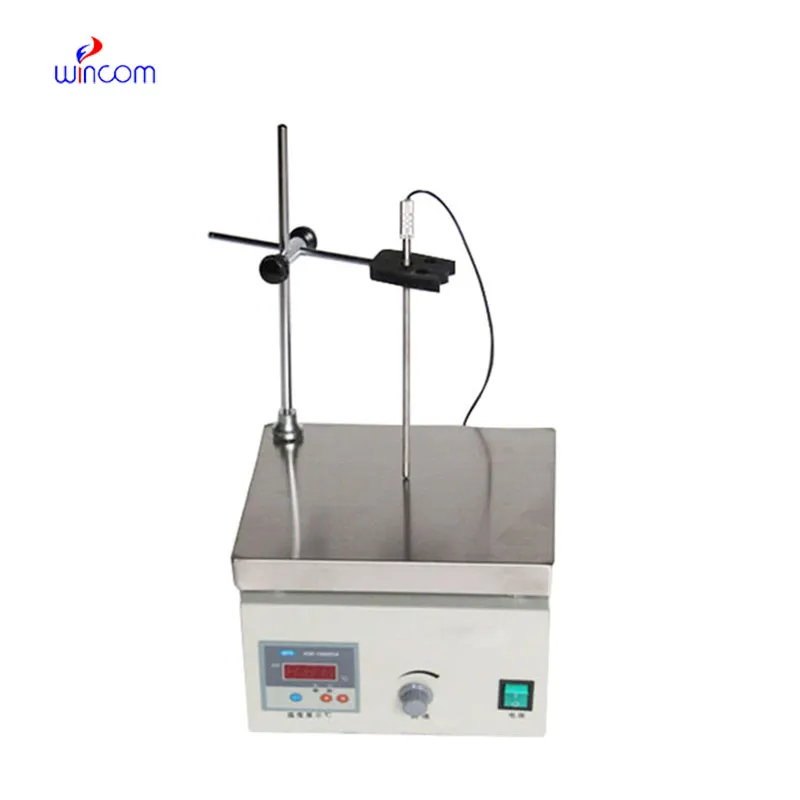

We’ve used this centrifuge for several months now, and it has performed consistently well. The speed control and balance are excellent.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Hello, I’m interested in your water bath for laboratory applications. Can you confirm the temperat...

We are planning to upgrade our imaging department and would like more information on your mri machin...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China