Recent innovations in cold press juicers vs centrifugal technology focus on the improvement of automation as well as information integration. Intelligent models now communicate with laboratory information management systems so that the recording of experimental parameters is no longer problematic. Noise reduction modules and ergonomic covers have also increased user comfort and safety. Also, controlled temperature chambers and high-speed rotors facilitate the handling of sensitive material without degradation. Such technology renders cold press juicers vs centrifugal equipment more adaptable to varying research needs, offering unparalled precision in particle separation and purification processes in countless industries.

cold press juicers vs centrifugal are part and parcel of the functioning of modern laboratories and factories. Applications include cell culture harvesting, purification of enzymes, and waste handling. In oil processing, they facilitate hydrocarbon/water separation. Clinical laboratories depend on cold press juicers vs centrifugal for accurate diagnostic tests, and chemical industries use them to purify chemicals and recover active ingredients. They also hold great importance in educational research, where repetition and accuracy are necessary to experimentation. This wide application reveals the extent to which cold press juicers vs centrifugal continue to drive scientific and industrial advancement globally.

cold press juicers vs centrifugal will integrate digital intelligence and cutting-edge engineering in the years to come. Complex algorithms will auto-tune parameters for optimum efficiency and safety. Energy-optimized designs will keep operating costs at a minimum and help support global green efforts. Robotics integration will facilitate round-the-clock unattended operation in big production setups. Modular design will provide ease of customization, allowing users to set up cold press juicers vs centrifugal for specific scientific or industrial uses. These improvements will allow cold press juicers vs centrifugal to not only increase performance but also establish new standards for automation, accuracy, and sustainability in the lab environments of the future.

Maintenance procedure routines protect the performance and safety of cold press juicers vs centrifugal. The rotor needs to be visually inspected before each operation for cracks or corrosion. Mild detergents are needed for cleaning, followed by thorough drying to prevent rust. Calibration verification and vibration monitoring assist in keeping it accurate. The instrument should be set on a level surface to reduce stress on bearings. During storage, cold press juicers vs centrifugal must be kept covered and not plugged to keep electronics safe. Under operator discipline and regular maintenance, laboratories can offer years of trouble-free performance.

A cold press juicers vs centrifugal operates by inducing centrifugal force through rapid rotation, separating substances according to mass and density. It has a critical use in laboratories, medical testing, and industrial treatment. In medicine, for instance, cold press juicers vs centrifugal facilitate plasma and serum separation for the purpose of diagnosis. In environmental science, they assist in the examination of suspended solids in water samples. Their robust build, combined with programmable functions and safeguarding features, facilitates fine speed control and timing. cold press juicers vs centrifugal continue to evolve to provide faster and more accurate separation procedures in various fields.

Q: What is a centrifuge used for? A: A centrifuge is used to separate mixtures based on density differences by spinning them at high speeds, allowing heavier particles to settle away from lighter ones. Q: How does a centrifuge work? A: A centrifuge operates by generating centrifugal force, pushing denser materials outward while lighter components remain near the center, resulting in effective separation. Q: What are common applications of a centrifuge? A: Centrifuges are used in laboratories, hospitals, and industries for blood testing, chemical analysis, purification, and sample preparation. Q: How often should a centrifuge be calibrated? A: Calibration should be performed at least once a year or whenever performance inconsistencies appear to ensure accuracy and reliability. Q: Can a centrifuge handle biological samples? A: Yes, many centrifuges are designed for biological materials such as blood, plasma, and cell cultures under controlled and sterile conditions.

I’ve used several microscopes before, but this one stands out for its sturdy design and smooth magnification control.

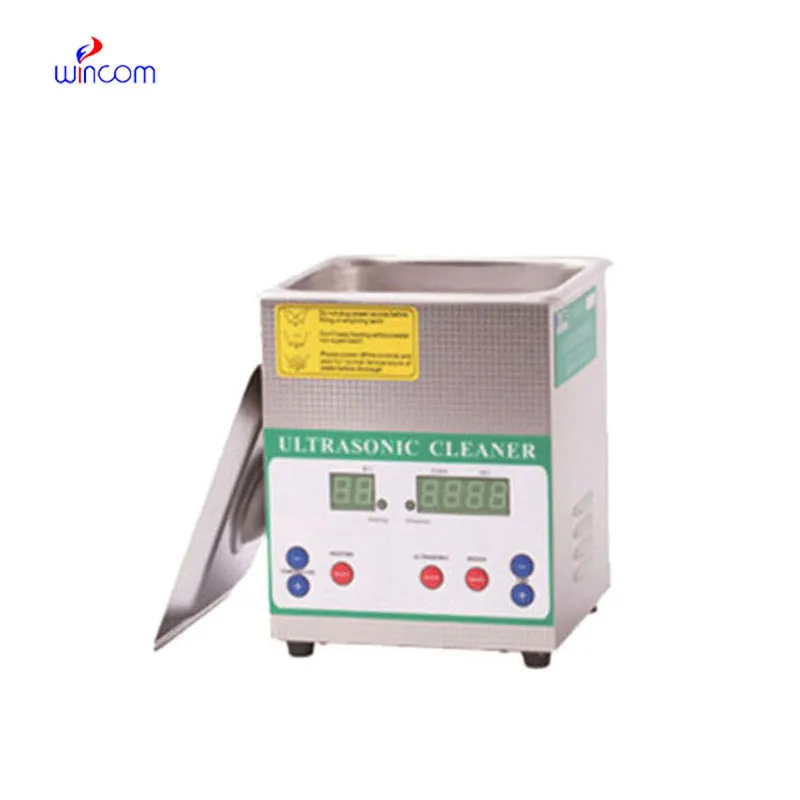

We’ve used this centrifuge for several months now, and it has performed consistently well. The speed control and balance are excellent.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We’re currently sourcing an ultrasound scanner for hospital use. Please send product specification...

Could you share the specifications and price for your hospital bed models? We’re looking for adjus...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China